Program Description

While it is important to understand that accidents happen, it is also a known fact that actions can be taken to mitigate the risks of these accidents. In 2008, workers’ compensation costs in the United States accounted for more than one billion dollars per week1. That is a lot of money that can be utilized more efficiently, as well as a lot of injuries that can be addressed with early intervention. Nastasi, Coutu, and Tcaciuc highlight work-related musculoskeletal disorders as the occupational settings most costly problem, suggesting that identifying high risk individuals and implementing intervention programs will help reduce the human suffering and economic burdens for both employers and employees2. Additionally, lower healthcare costs, increased employee productivity, and higher level of morale among worksites can all be obtained with the implementation of a workplace wellness program3.

By having Certified Early Intervention Specialists (CEIS) on-site to provide employee education, injury triage, and address poor ergonomics, injury risks can be mitigated and overall wellness of the workforce can be improved.

Facility Demographics

4 swing shift groups (A, B, C, and D)

Day Crew shift and Salary/Administrative staffSwing shift working 7 days on/2 days off, or 5 days on/2 days off (rotating shifts weekly)

Plants average 200-400 full-time employees2 Unions: Glass, Molders, Pottery, Plastics and Allied Workers International Union (GMP) and United Steelworkers (USW)Manufacturing

History On-Site

Prior to 2011, the glass manufacturing company hired an on-site nurse or occupational doctor who treated in a reactionary approach versus a preventative approach.

In 2011, the glass manufacturing company decided to work with ATI Worksite Solutions (AWS) to incorporate a full-time CEIS at one pilot site. A CEIS has exceptional knowledge in dealing with musculoskeletal injuries and the pilot plant saw success. It was decided to hire a part-time CEIS for a second plant later that year; this position quickly grew into a full-time program. The company saw such a reduction of workers’ compensation costs that AWS expanded to three more plants in 2012 and another three plants in 2013. AWS expanded to their 9th site within this company in 2015 and 10th site in 2016. Currently an expansion to an 11th site is planned for 2017.

AWS Objectives

Initially, the main goal of AWS was to help reduce workers’ compensation injuries, particularly soft tissue injuries. Now, AWS continues to focus on this overall goal by executing smaller goals, like increasing employee engagment and education for both wellness and injury prevention.

Results Achieved

One of the biggest goals of the AWS Early Intervention Program is to treat injuries early by providing preventative care and education. With early intervention we can help to eliminate aches and pains and prevent exacerbation and recurrence.

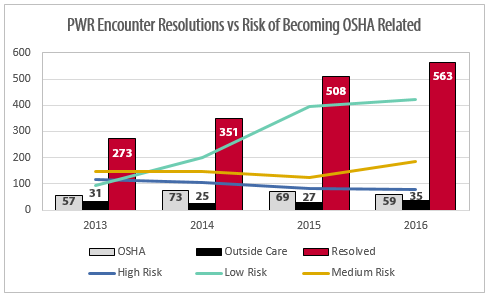

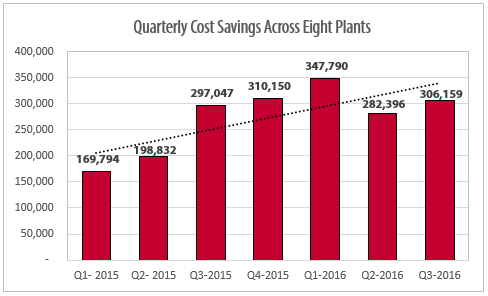

Since 2013, early intervention has decreased high risk of becoming OSHA recordable injuries from 35% to 12% of all injuries reported. We have also seen an overall decrease in the number of OSHA recordables across these sites. By reaching employees early we are also able to increase company cost savings which has nearly doubled in the last 21 months.